The Versatility of Angle Iron in Metal Fabrication in Australia

Angle iron, a fundamental component in the world of metal fabrication, plays a pivotal role in shaping structures across various Australian industries. As a reputable metal fabricator and supplier in Newcastle, Ezimetal understands the importance of angle iron in construction, manufacturing and DIY projects. In this blog post, we’ll discuss the diverse applications, remarkable versatility, strength and durability of angle iron.

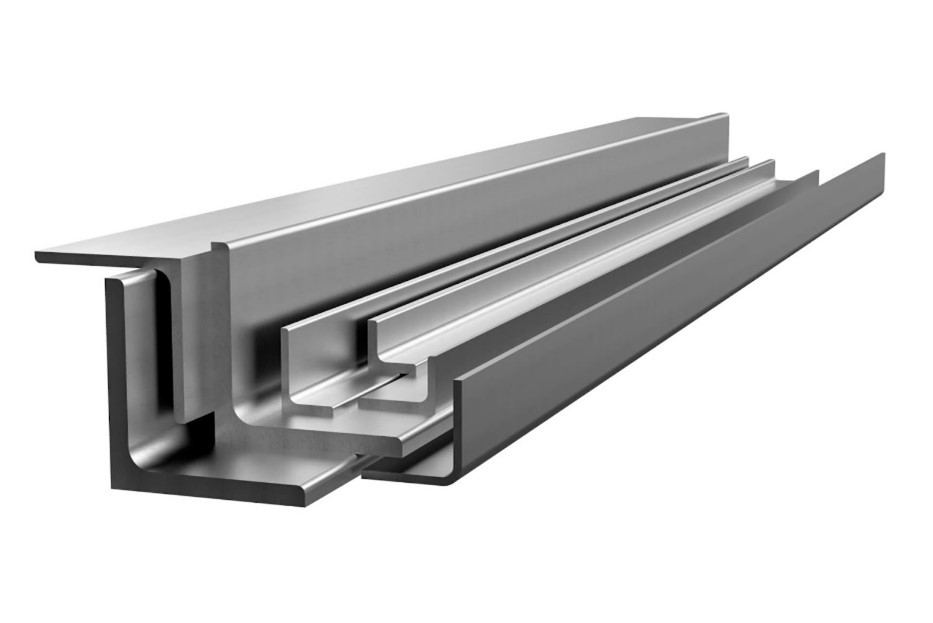

Uses and Applications

Angle iron finds its place in an extensive array of applications, making it a cornerstone in metal fabrication projects. In the construction sector, it serves as a crucial building material for framing structures, providing strength and support. Manufacturers utilise angle iron in creating durable components for machinery and equipment, benefiting from its ability to withstand heavy loads and harsh conditions. DIY enthusiasts also recognise its value in crafting everything from shelving units to custom furniture. With Ezimetal’s range of angle iron sizes and angle iron dimensions, the possibilities are virtually limitless.

Versatility

One of the standout features of angle iron lies in its versatility. Metal fabricators can easily cut, weld and shape angle iron to meet the specific requirements of diverse projects. Its malleability allows for intricate designs, making it an ideal choice for architects and designers seeking both functionality and aesthetics. From creating sturdy brackets to constructing intricate frameworks, angle iron proves to be an indispensable tool for metal fabricators across industries.

Strength and Durability

Angle iron is renowned for its exceptional strength and durability, making it a preferred material for load bearing and support applications. Its L-shaped profile enhances structural integrity, ensuring stability in various projects. Whether it’s providing essential support in construction or forming a robust framework for heavy machinery, angle iron’s resilience makes it a reliable choice in the world of metal fabrication. The galvanised angle iron available at Ezimetal further enhances its durability, protecting against corrosion and extending its lifespan.

Ezimetal’s Tips for Usage

To maximise the effectiveness of angle iron in metal fabrication projects, consider the following tips:

- Precision Cutting: Invest in quality cutting tools to ensure precise angles and dimensions for your projects.

- Welding Techniques: Employ proper welding techniques to maintain the structural integrity of angle iron joints.

- Corrosion Prevention: Opt for galvanised angle iron to enhance resistance against corrosion, especially in outdoor or humid environments.

- Customisation: Leverage the versatility of angle iron by customising it to fit unique project requirements, promoting both functionality and aesthetics.

Explore the Ezimetal Range of Angle Iron

Angle iron is a versatile and indispensable material in the metal fabrication industry. Its applications span across construction, manufacturing and DIY projects, showcasing its adaptability and reliability. With Ezimetal‘s comprehensive range of angle iron sizes and dimensions, the possibilities for innovative and sturdy creations are endless.

Contact us online or call 02 4987 4210 for expert guidance or a custom quote.